The construction sector is experiencing a swift reconfiguration spurred by a wave of novel methodologies and advanced technologies. These innovations extend beyond incremental improvements; they signify a redefinition of the paradigms governing the conception, erection, and stewardship of contemporary edifices. The present-day environment mandates workflows that compress time, minimize resource consumption, respect ecological mandates, and remain resilient to variable labor availability.Forward-thinking commercial contractors Denver are at the leading edge of this transformation, employing sophisticated methods that raise the bar for quality, sustainability, and operational efficiency across a wide range of commercial projects.By endorsing and advancing these pioneering strategies, these firms affirm their role in forging a sustainable and progressive trajectory for the entire industry.

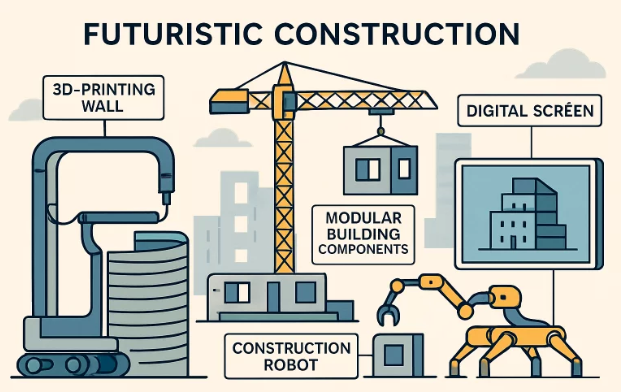

Innovative construction professionals consistently adopt an array of smart technologies and environmentally sustainable materials, while also deploying robotics and digital fabrication techniques, to respond to an increasingly complex set of societal and commercial demands. Breakthroughs such as additive manufacturing, off-site prefabrication, and autonomous assembly lines drive measurable productivity improvements and simultaneously alleviate persistent labor shortages and rigorous environmental performance requirements. When these tools are strategically integrated, project schedules contract, financial outlays decline, and overall quality is enhanced. Moreover, the newfound design freedom afforded by such technologies allows architects to realise geometries and performance criteria that were previously impractical. In this manner, the modern construction sector reinforces its critical contribution to the fabrication of resilient and sustainable built environments that will serve the needs of coming generations.

3D Printing in Construction

Three-dimensional printing is emerging as a defining advancement in modern construction practice. Large-format additive manufacturing systems fabricate structural components by successively depositing material from parametric digital files. This process confers several notable benefits. Spatial design is liberated from the constraints of conventional formwork; engineers and architects can articulate sophisticated geometries and non-linear surfaces that would otherwise entail prohibitive formwork expense or technical limitation. Productivity is similarly enhanced; in a pioneering Dubai undertaking, a 250-square-metre administrative pavilion was realised in 17 working days, yielding a 50-per-cent contraction in workforce hours and a 60-per-cent reduction in material off-cuts. Such acceleration and economy are particularly advantageous in commercial contexts, where contractual timelines and fixed-price bidding exert stringent pressure on programme and on-cost.

Modular and Prefabricated Construction

Modular and prefabricated construction methods are fundamentally transforming contemporary building practices. Rather than fabricating each component on the construction site—an approach vulnerable to weather delays and complicated logistics—substantial structure segments are produced in controlled factory environments and subsequently shipped to the assembly site. This factory-based manufacturing significantly compresses the overall project timeline: modular systems frequently achieve completion in half the time required by conventional methods, while maintaining uniform, high-quality outcomes. Furthermore, the reduced on-site fabrication minimizes noise, dust, and disruptions, rendering the approach especially suitable for dense urban environments or constrained lots. A representative case is the modular construction of a large metropolitan hospital, which was delivered in six months instead of the two-year schedule typically assigned to a ground-up, site-based assembly. Amid growing environmental scrutiny, the resource efficiency and waste minimization inherent to modular construction are drawing the sustained interest of developers and design teams striving to meet accelerated schedules and stringent sustainability certifications.

Smart Materials and Sustainable Solutions

Innovative materials are crucial to the global drive for high-performing and sustainable construction. A hallmark of this field is self-healing concrete, which incorporates microorganisms that trigger a calcite-forming reaction when moisture infiltrates a crack. The result is an autonomous sealing process that not only repairs damage but also prolongs the service life of the concrete, thereby diminishing the frequency and expense of upkeep. In parallel, Building Integrated Photovoltaics (BIPV) are redefining building skins by embedding photovoltaic cells directly into windows and curtain walls, turning the façade into a distributed energy source. As highlighted in a U.S. Department of Energy article, expanding access to solar technology through rooftop systems and integrated solutions is key to advancing energy equity and efficiency. These innovations cut energy demand, minimize lifecycle costs, and bolster a building’s capacity to withstand climatic extremes, all supporting international sustainability benchmarks. Stakeholders now prefer developments that contribute positively to global ecological health, thereby transforming the employment of these materials into an ethical necessity and a distinctive market edge.

Robotics and Automation on Construction Sites

Growing commitments to safety, velocity, and precision propel robotics and automation to core roles across modern construction sites. Take automated bricklaying systems: working at unprecedented scales, they can lay thousands of blocks per shift, consistently eclipsing even the finest masons in cadence and geometric fidelity. Beyond masonry, robotics is transferring itself—or at least its manipulators—to the industry’s most perilous tasks, whether applying protective coatings to glass-clad high-rises, top-down demolition of stressed structures or executing precision welds on airborne connections. These deployments translate directly to lower incident rates and reduced exposure for the supervisory workforce. Complementing this, semi-autonomous drones are now standard for aerial site mapping, stockpile quantification and temperature-differential thermography, delivering orthomosaics and heat maps that fine-tune logistics and quality control in near-real time. The edge extends well beyond the perimeter fence: agile robotic arms preassemble mechanical racks in climate-controlled bays. At the same time, autonomous trucks and robotic hoists manage on-site material shuttle cycles. Pioneers across these fronts are documenting double-digit upticks in throughput, conspicuous drops in rework, and marked stabilization of variance-driven cost overruns.

Building Information Modeling (BIM) and Digital Twins

The digital transformation sweeping through construction is epitomized by Building Information Modeling (BIM) and the emerging concept of digital twins. BIM provides a collaborative platform in which architects, engineers, contractors, and other stakeholders can interact within a rich, geometrically and parametrically defined digital representation of the project. By mapping every component and construction phase in advance, the system facilitates early visualization and rigorous clash detection, mitigating the risks of costly rework, miscommunication, and project delays. The result is a streamlined progression that carries consistency and clarity from early design to physical execution. Digital twins extend the BIM concept by evolving static design representations into the completed asset’s dynamic, real-time digital counterparts. By continuously ingesting data on usage, environmental conditions, and system performance, these living models enable facility managers to foresee maintenance requirements, forestalling costly repairs and optimizing operational efficiency over the entire building lifecycle. The complementary adoption of BIM and digital twins fosters enhanced transparency, operational efficiency, and financial prudence, affecting both the construction phase and the enduring performance of the facility. Empirical research indicates that such integrated practices can reduce total maintenance costs by up to 20 percent, rendering them essential instruments for project owners whose priorities are sustained long-term value.

Internet of Things (IoT) and Smart Buildings

The Internet of Things (IoT) rapidly converts traditional edifices into responsive, self-optimizing environments. By integrating clusters of intelligent sensors and responsive actuators across critical building subsystems—namely heating, ventilation, and air conditioning (HVAC), illumination, security networks, and hydraulic distribution—owners gain the ability to observe and modulate energy consumption, thermal comfort, occupancy trajectories, and maintenance timelines in an instantaneous and data-driven manner. The resulting web of coordinated functions elevates occupant well-being and security and yields substantial economic advantages by revealing latent inefficiencies and rectifying faults at incipient stages. The combination of prognostic maintenance algorithms and autonomously modulated controls minimizes unscheduled interruptions and prolongs the useful life of capital investments. As the technology matures, smart buildings are emerging as the benchmark across the sector, equipping facility operators with detailed, predictive analytics. At the same time, tenants enjoy environments that are both healthier and more responsive to their needs. Such innovations catalyze the construction of subsequent buildings that harmonize exceptional operational performance with reduced environmental impact.

The incorporation of cutting-edge technologies—encompassing robotics, parametric design, responsive materials, and pervasive connectivity— is redefining the workflows of construction and the characteristics of the resultant built fabric. Organisations that embrace these anticipatory approaches can execute more rapid, secure, sustainable, and economically viable projects, thereby satisfying the dynamic demands of society and the biosphere. Ongoing technological advancement ensures that enterprises prioritizing innovation will determine the trajectory of the sector and its constructive influence on communities across the globe.