As industries evolve, the demand for advanced and intelligent solutions to protect critical equipment has never been higher. Traditional enclosures provide essential protection, but the rise of smart industrial enclosures is revolutionizing the way businesses monitor, maintain, and optimize their equipment. These next-generation enclosures integrate advanced technologies such as IoT connectivity, remote monitoring, and automated climate control to enhance performance, improve efficiency, and ensure equipment longevity.

For businesses seeking cutting-edge protection, exploring innovative Industrial Enclosures can significantly improve equipment reliability and efficiency.

1. What Are Smart Industrial Enclosures?

Smart industrial enclosures are protective housings equipped with intelligent features to monitor and safeguard electrical, mechanical, and networking equipment. Unlike conventional enclosures, smart enclosures come with embedded sensors, communication modules, and automated control systems that allow real-time monitoring and remote management.

These enclosures are used across various industries, including manufacturing, telecommunications, renewable energy, and industrial automation. By incorporating smart technologies, businesses can minimize downtime, reduce maintenance costs, and enhance operational efficiency.

2. Key Features of Smart Industrial Enclosures

IoT and Remote Monitoring

Smart enclosures are equipped with IoT-enabled sensors that continuously track internal conditions such as temperature, humidity, airflow, and pressure. These sensors send real-time data to a cloud-based platform, allowing remote monitoring and instant alerts for any irregularities.

Automated Climate Control

Sensitive equipment requires precise environmental conditions to function optimally. Smart enclosures feature:

- Active Cooling Systems: Automated air conditioners, heat exchangers, or fans that adjust based on temperature fluctuations.

- Heaters and Dehumidifiers: Prevent moisture buildup and condensation in humid environments.

- Smart Ventilation: Automatically adjusts airflow to maintain optimal conditions.

Predictive Maintenance and Self-Diagnostics

Using AI-powered analytics, smart enclosures can detect early signs of wear and tear, allowing businesses to conduct maintenance before a failure occurs. This predictive maintenance approach helps reduce downtime and extend the lifespan of enclosed equipment.

Real-Time Security and Access Control

Smart industrial enclosures enhance security with:

- Biometric Access: Fingerprint or facial recognition for authorized personnel only.

- Remote Locking Mechanisms: Allows administrators to lock or unlock enclosures remotely.

- Tamper Detection: Alerts operators if unauthorized access or physical tampering is detected.

Energy Efficiency and Sustainability

Many smart enclosures feature energy-saving technologies such as:

- Solar-Powered Operations: Enclosures in remote locations can operate using solar panels.

- Adaptive Energy Use: Automatically adjusts power consumption based on demand.

- Recyclable Materials: Designed using eco-friendly materials to reduce environmental impact.

3. Applications of Smart Industrial Enclosures

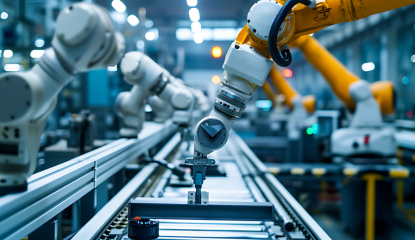

Industrial Automation and Manufacturing

Smart enclosures protect robotic controllers, PLCs (Programmable Logic Controllers), and motor drives, ensuring seamless industrial automation with minimal interruptions.

Telecommunications and Data Centers

Networking equipment such as servers, fiber optics, and wireless communication devices benefit from real-time monitoring and automated cooling systems in smart enclosures.

Renewable Energy Sector

Solar power stations and wind farms use smart enclosures to monitor power inverters, battery storage units, and electrical panels, ensuring stable energy distribution.

Oil, Gas, and Hazardous Environments

In extreme conditions, smart enclosures offer explosion-proof protection, remote surveillance, and environmental monitoring to maintain equipment integrity and safety.

4. Benefits of Smart Industrial Enclosures

Increased Equipment Reliability

Real-time monitoring and predictive maintenance reduce failures, extending the lifespan of enclosed equipment.

Reduced Maintenance Costs

Automated alerts and self-diagnostic capabilities help schedule maintenance efficiently, preventing costly emergency repairs.

Enhanced Security and Access Control

Smart access control systems protect sensitive equipment from unauthorized access and security threats.

Remote Monitoring and Control

Operators can monitor enclosure conditions from anywhere, ensuring rapid response to potential issues.

Energy Savings and Sustainability

Adaptive power management and eco-friendly designs contribute to lower energy consumption and reduced carbon footprints.

5. The Future of Smart Industrial Enclosures

AI and Machine Learning Integration

Future smart enclosures will incorporate AI-driven analytics to predict maintenance needs with even greater accuracy and efficiency.

5G and Enhanced Connectivity

With the rise of 5G networks, smart enclosures will have faster, more reliable communication capabilities, improving remote management and automation.

Self-Healing Materials and Nanotechnology

New materials will enable enclosures to repair minor damages, reducing wear and tear and extending service life.

6. Conclusion

Smart industrial enclosures represent the future of equipment protection, offering unparalleled monitoring, security, and efficiency. Industries adopting these advanced enclosures benefit from reduced downtime, lower maintenance costs, and enhanced operational safety. As technology continues to advance, the integration of AI, IoT, and automation in enclosures will further revolutionize industrial infrastructure.